- Stock: Out Of Stock

- Model: AC611-161-00

- SKU: AC611-161-00

- UPC: 6009515880774

Available Options

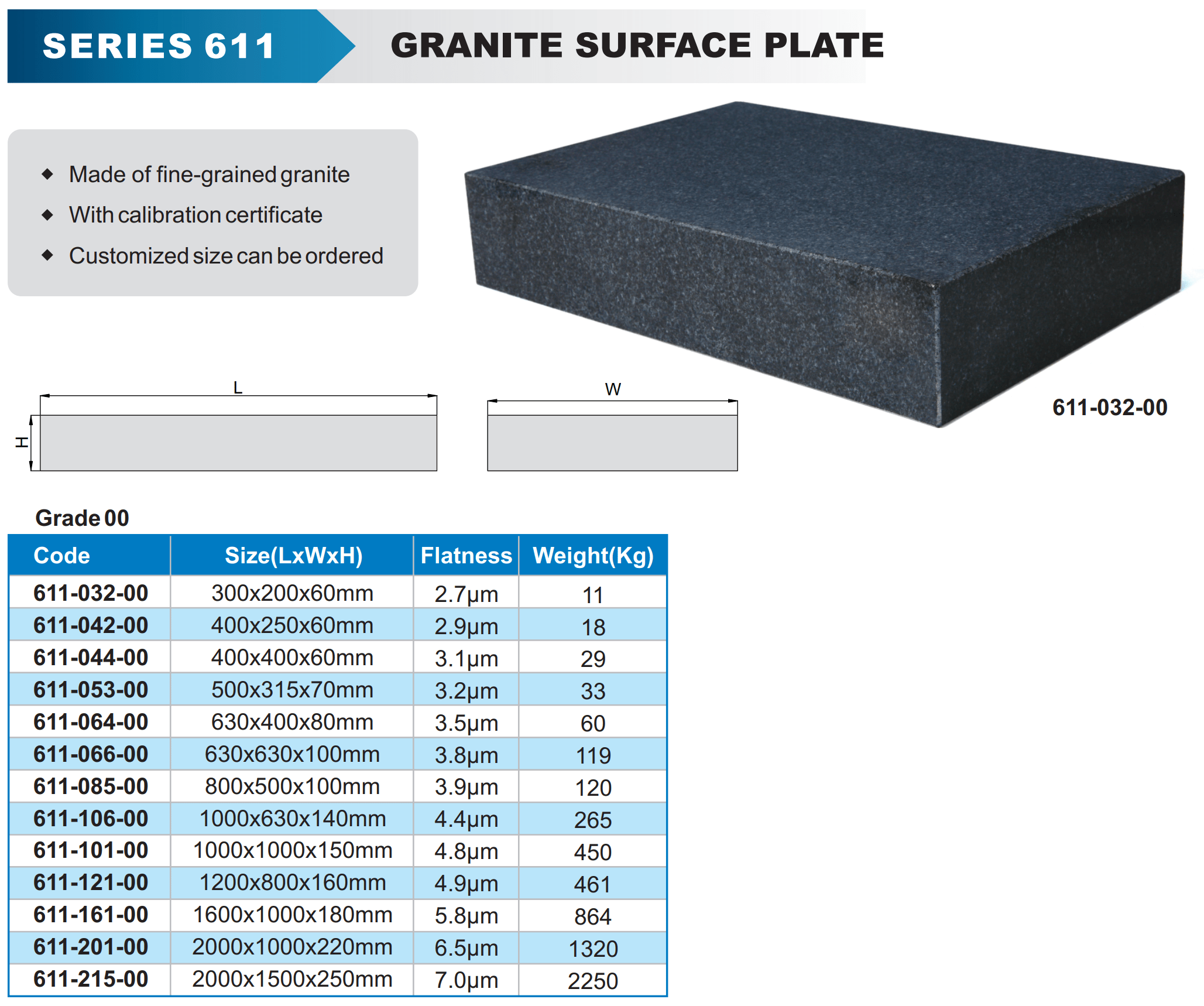

SERIES 611

A granite surface plate is a flat, stable reference surface made from high-quality, precision-ground granite. It is primarily used in industrial and laboratory environments for precise measurement and inspection tasks. The stability, durability, and wear resistance of granite make it an ideal material for surface plates, particularly for maintaining accuracy over time under heavy use.

Applications of a Granite Surface Plate:

-

Precision Inspection:

- Surface plates are used as a reference plane for inspecting parts for flatness, squareness, parallelism, and other geometrical dimensions. Instruments such as dial indicators, height gauges, and CMM (Coordinate Measuring Machines) are often used in conjunction with a surface plate to measure parts accurately.

-

Layout Work:

- In manufacturing or machining, granite surface plates are used as the base for marking out precise locations on a workpiece, especially for holes, cutouts, or assembly points.

-

Calibration:

- Tools like micrometers, calipers, and dial indicators are often calibrated against a granite surface plate, ensuring that they are accurate when used for measurement.

-

Precision Assembly:

- Surface plates serve as a platform for assembling precision components, allowing for consistent alignment and the elimination of errors in fit or dimension.

-

CMM Base:

- In coordinate measuring machines (CMMs), granite is often used as the base plate because of its dimensional stability, ensuring the CMM performs consistently and accurately.

Advantages of Using Granite Surface Plates:

-

Superior Flatness:

- Granite can be ground and lapped to an incredibly high degree of flatness, offering a reference surface that remains consistent over time.

-

Non-reactive:

- Granite does not rust, corrode, or react chemically with most materials, making it ideal for use in various environments, including labs with sensitive equipment.

-

Thermal Stability:

- Granite has a low coefficient of thermal expansion, meaning it doesn’t expand or contract significantly with temperature changes, maintaining accuracy across different environments.

-

Long Lifespan:

- Due to its hardness and durability, granite surface plates last for many years with minimal wear. They are much more resistant to scratches and damage compared to steel plates.

-

Vibration Dampening:

- Granite naturally absorbs vibrations, which helps ensure more accurate measurements by minimizing disturbances when working with sensitive instruments.

A granite surface plate is an essential tool in precision measurement, offering a stable, flat reference surface for inspection, calibration, and layout tasks. Its natural durability, accuracy, and resistance to environmental factors make it ideal for industries where precision is paramount, such as aerospace, automotive, and industrial manufacturing.

Maintenance and Care:

- Cleanliness: Surface plates should be kept clean and free of dust, oil, or other contaminants. Even tiny particles can affect the accuracy of measurements.

- Regular Calibration: Despite their durability, granite plates need regular recalibration to ensure they maintain their flatness, especially in high-use environments.

- Proper Storage: When not in use, surface plates should be covered to protect them from dust or damage.

Key Features of a Granite Surface Plate:

-

Material:

- Granite is used because of its hardness, density, and resistance to wear and corrosion. It is not as affected by temperature changes as metal, which makes it highly dimensionally stable.

- The granite used is typically black granite, chosen for its fine grain structure, minimal porosity, and excellent resistance to wear.

- Non-magnetic and non-conductive, granite does not interfere with magnetic or electronic measuring instruments.

-

Flatness and Accuracy:

- The primary function of a granite surface plate is to provide a reference flat surface. Granite surface plates are manufactured to very tight tolerances, with variations in flatness measured in microns (millionths of a meter).

- These plates come in different grades of accuracy:

- Grade 00 (Laboratory Grade): The highest accuracy, used in metrology labs.

- Grade 0 (Inspection Grade): Suitable for precise inspection work in factories and labs.

- Grade 1 (Toolroom Grade): Used in general manufacturing and toolrooms for less critical measurement and layout tasks.

-

Dimensional Stability:

- Granite surface plates are highly stable over time and are resistant to warping, bending, or expanding due to changes in humidity or temperature.

- The natural material resists wear better than metal plates and maintains its flatness over long periods of use.

-

Size:

- Granite surface plates come in a wide variety of sizes, from small plates used for bench work (e.g., 300 mm x 300 mm or 12 inches x 12 inches) to large plates for industrial use (e.g., 2000 mm x 3000 mm or 6 feet x 10 feet).

- Plates are available in both metric and imperial dimensions, depending on the specific needs of the industry or region.

-

Calibration and Traceability:

- Granite surface plates are calibrated against reference standards to ensure that they meet specific flatness and accuracy requirements.

- Many come with a calibration certificate to show they have been inspected and are traceable to national or international standards, such as ISO 9001 or NIST (National Institute of Standards and Technology).

- Regular recalibration is recommended to ensure the plate maintains its accuracy, particularly in high-use environments.

-

Resistance to Damage:

- Granite plates are extremely durable and resistant to damage like scratches, nicks, and corrosion. They are harder than most steels, which makes them ideal for environments with heavy-duty use.

- If a small area is damaged, it is often localized and does not affect the overall flatness of the surface, unlike metal plates which can warp or dent.

-

Support and Leveling:

- For proper use, granite surface plates must be supported evenly to avoid any distortion in the flatness. They are usually mounted on special stands or frames with adjustable feet to ensure the plate remains perfectly level.

- High-precision plates often come with adjustable stands that allow fine-tuning to maintain the plate&s flatness under various working conditions.

Technical Specifications