- Stock: 15

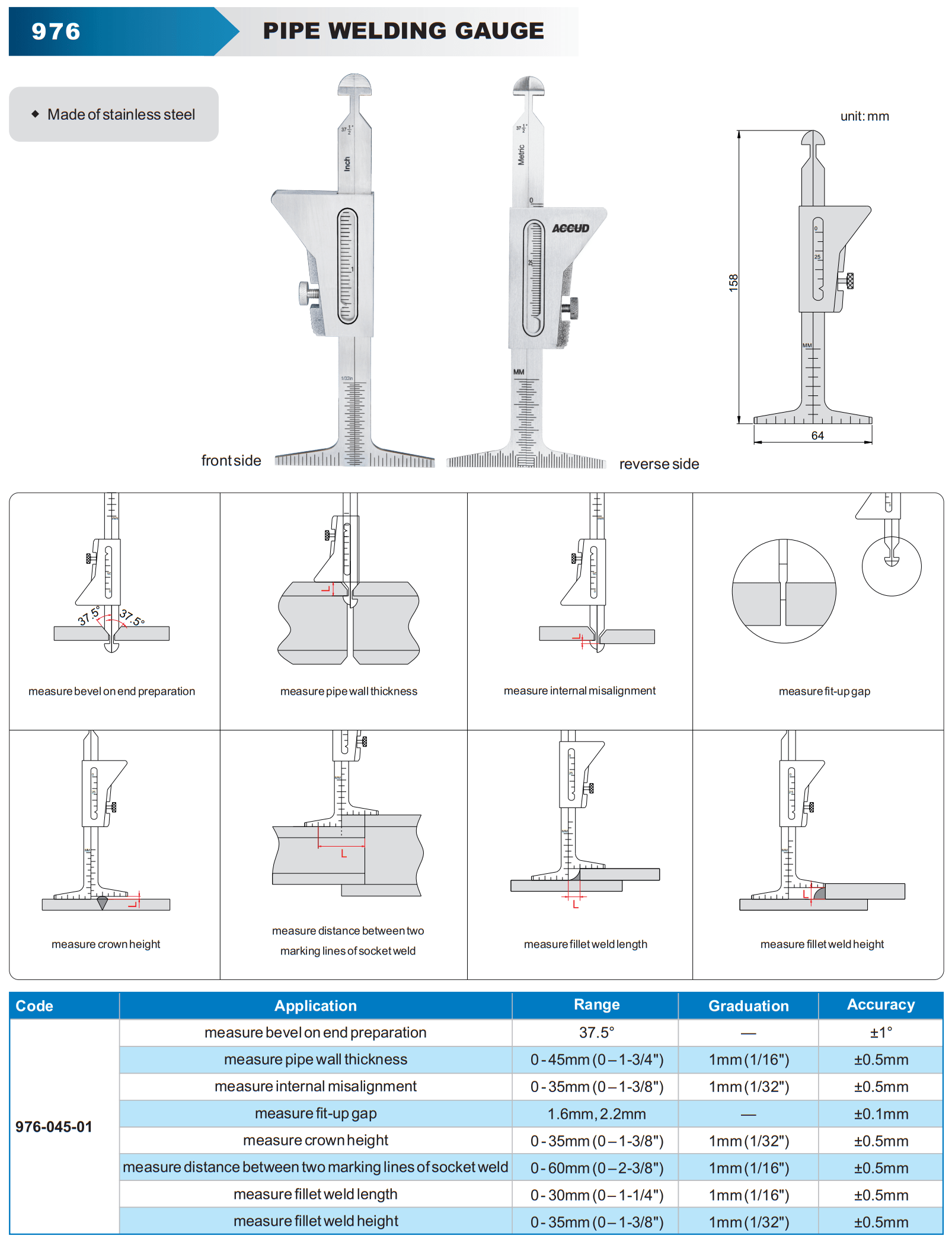

- Model: AC976-045-01

- Weight: 0.30kg

- Dimensions: 255.00mm x 98.00mm x 35.00mm

- SKU: AC976-045-01

- UPC: 6009515850463

Available Options

SERIES 976

A Pipe Welding Gauge is a specialized tool designed to measure various dimensions and features of pipe welds, ensuring the quality, accuracy, and safety of the welds. It is used in industries such as oil and gas, shipbuilding, construction, and pipelines, where welding is critical to the integrity of the structure. The pipe welding gauge helps check parameters like root openings, alignment, and weld reinforcement, providing welders and inspectors with a reliable method for ensuring that welds meet required specifications and industry standards.

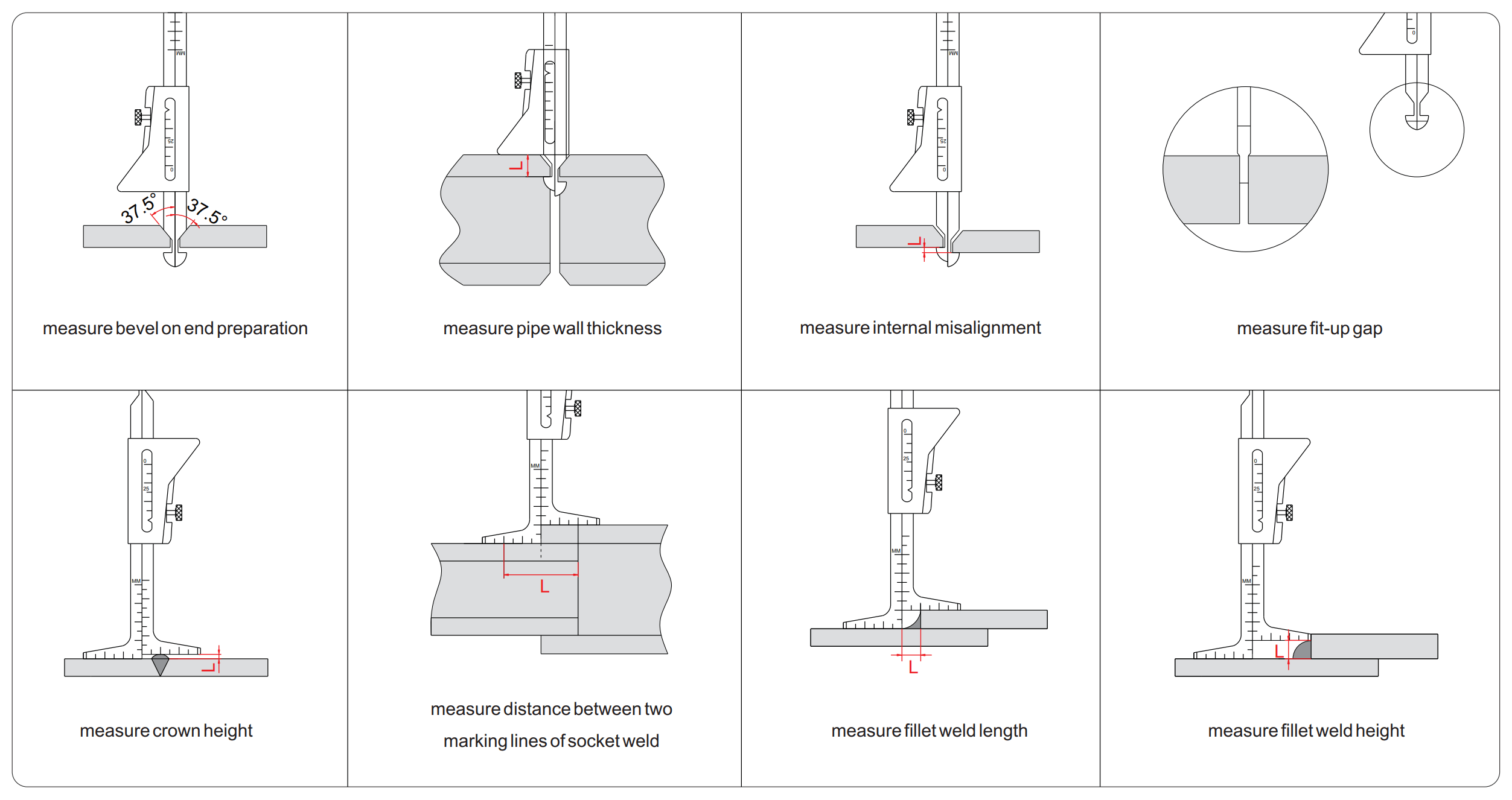

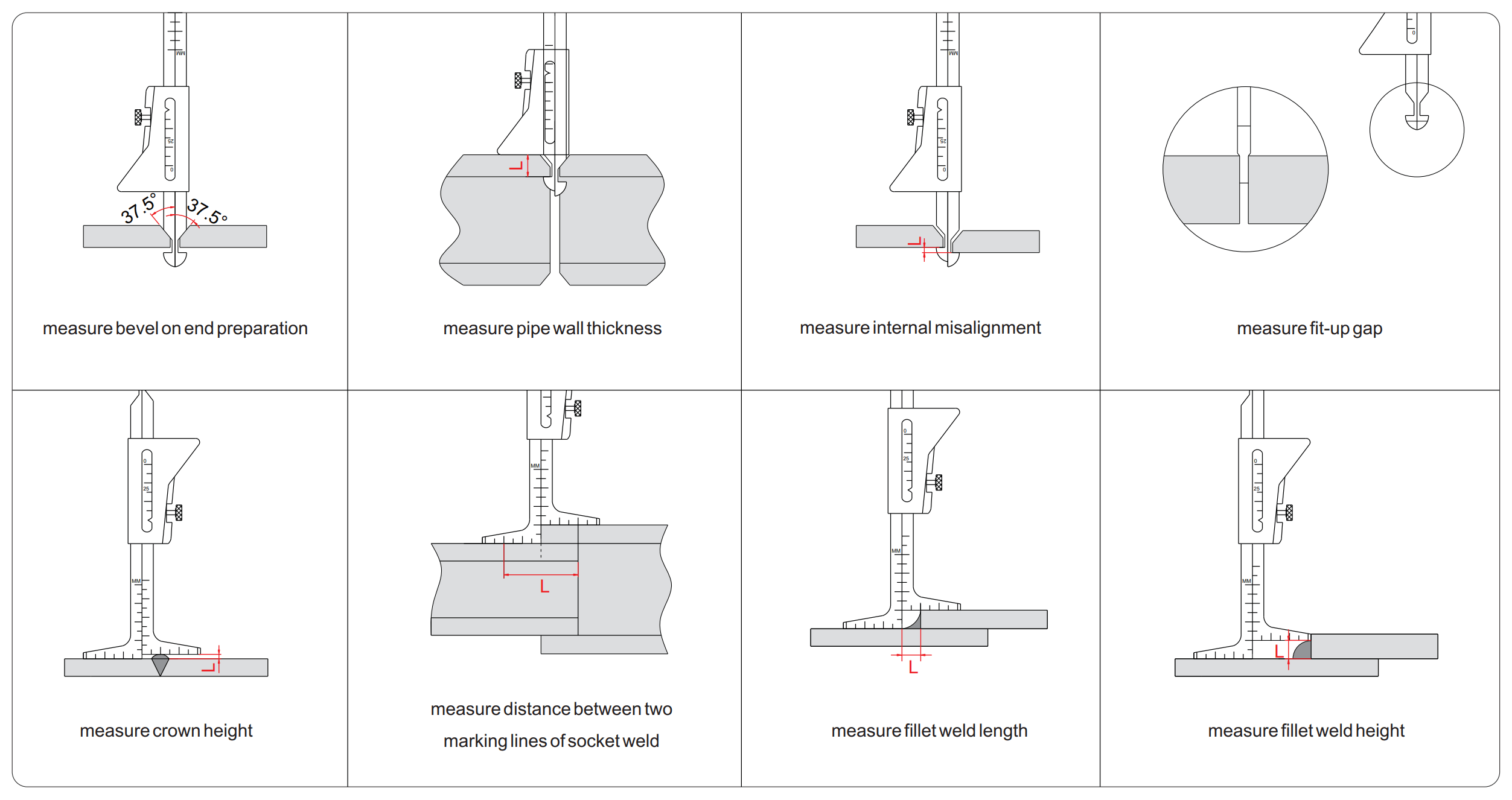

- measure bevel on end preparation

- measure pipe wall thickness

- measure internal misalignment

- measure fit-up gap

- measure crown height

- measure distance between two marking lines of socket weld

- measure fillet weld length

- measure fillet weld height

Applications

-

Weld Inspection:

- Quality Control: Used to inspect pipe welds to ensure they meet the required specifications for size, alignment, and reinforcement, according to industry standards such as AWS (American Welding Society) or ISO.

- Weld Consistency: Helps to check for uniformity and consistency across the welds, ensuring proper bonding and structural integrity.

-

Pipeline and Oil & Gas Industries:

- Pipeline Welding: Widely used in pipeline construction and maintenance, particularly in oil and gas applications, to inspect pipe joints and ensure high-quality welds that prevent leaks and structural failures.

- On-Site Field Use: Ideal for fieldwork in remote or challenging environments where pipelines are constructed or repaired, ensuring accurate welds in the field.

-

Shipbuilding and Heavy Machinery:

- Large-Diameter Pipes: Used in shipbuilding and heavy machinery industries, where large-diameter pipes are welded, to ensure proper alignment, reinforcement, and gap sizes during the welding process.

-

Construction and Fabrication:

- Structural Piping: Ensures proper welding of structural piping in construction projects, preventing issues that could affect the safety and performance of the piping system.

-

Training and Education:

- Welding Training: Often used in welding schools and apprenticeship programs to teach proper pipe welding techniques and quality control practices.

How to Use a Pipe Welding Gauge:

-

Measure Weld Reinforcement: Place the gauge across the weld to check the height of the reinforcement. Ensure the reinforcement height is within the specified limits to avoid excessive material buildup.

-

Check Root Opening (Gap): Insert the appropriate section of the gauge between the pipe ends to measure the root opening before welding. Ensure that the gap is even and within the required range.

-

Pipe Alignment Measurement: Use the alignment feature to check if the two pipe sections are properly aligned. This ensures that the pipes are in the correct position for welding.

-

Hi-Lo Measurement: For internal alignment (hi-lo condition), insert the Hi-Lo gauge between the pipes to measure the internal mismatch. Proper alignment is essential for strong and smooth welds.

-

Check Undercut Depth: Use the gauge to measure the depth of any undercut along the weld toe. Ensure the undercut depth is within acceptable limits to prevent weakening of the joint.

A Pipe Welding Gauge is an indispensable tool for welders and inspectors involved in the construction and maintenance of pipelines, oil and gas facilities, shipbuilding, and other industries requiring high-quality pipe welding. Its ability to measure various dimensions such as reinforcement height, root gap, alignment, and undercut depth ensures that pipe welds meet strict safety and quality standards. With its durable design, multi-functional capabilities, and ease of use, the pipe welding gauge is essential for maintaining the integrity of welded pipe joints in demanding environments.

Advantages

- Multi-Functional: Offers multiple measurements with one tool, including gap, reinforcement, alignment, and more, making it versatile and efficient.

- Accurate: Provides highly accurate measurements for critical weld dimensions, ensuring weld quality and integrity.

- Durable and Long-Lasting: Made from materials like stainless steel, the gauge is designed to withstand tough working environments.

- Portable: Compact and easy to carry, ideal for welders working in the field or on large construction sites.

- Ensures Compliance: Helps ensure that pipe welds meet specific industry standards and specifications, reducing the risk of defects or failures.

Technical Specifications